General > Steel

Overview of Functions

Creates a general member with the properties of a steel.

General member is a function used for modeling atypical shapes. It is different from the modeling method of basic members (EX. Concrete Beam) as explained below.

General member

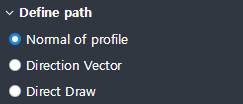

After creating a section (= cross section), the shape is created by extruding the section (Extrude) or by connecting the sections (Loft).Basic member

With the properties of the section (type, dimension, etc.) already set in the property window, the shape is created by drawing the center line directly.